One Factory: Overview, History, and Fascinating Facts

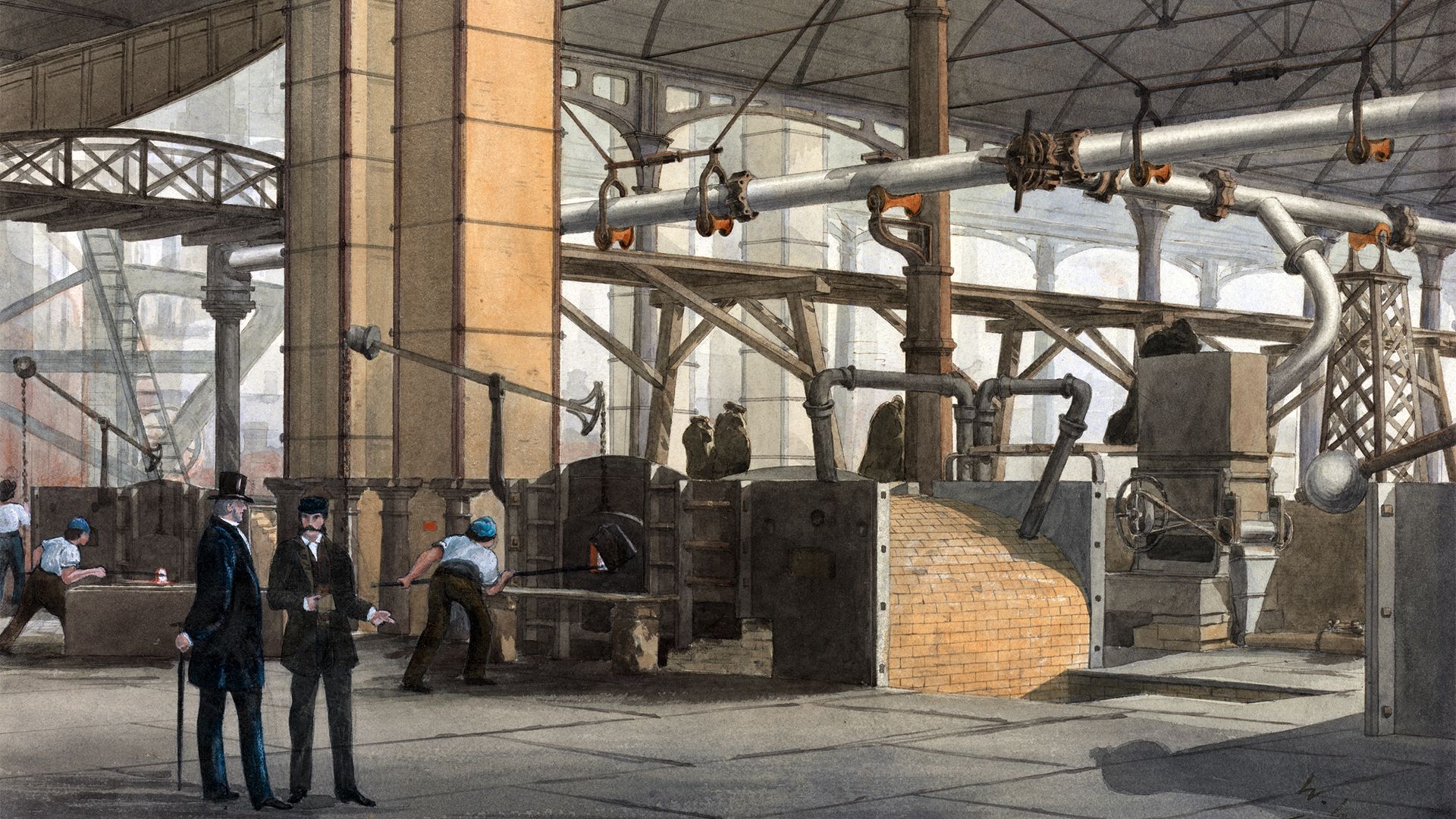

The factory system has been one of the most influential developments in modern economic history, fundamentally altering the landscape of production and labor. With the advent of the one factory concept during the Industrial Revolution, manufacturing transitioned from traditional home-based craftsmanship to large-scale industrial operations characterized by mechanization and specialization. The evolution of this system not only revolutionized how goods were produced but also significantly impacted the social and economic fabric of society.

As factories proliferated, they brought with them both remarkable efficiencies and serious challenges. The use of advanced technology, notably water and steam power, facilitated the rise of centralized manufacturing operations where a single one factory could produce vast quantities of goods. However, this paradigm shift was accompanied by profound changes in workers’ lives, leading to both progress and strife. In this article, we will explore the history, overview, innovations, and fascinating facts surrounding the factory system, while analyzing its impact on the modern world.

- Overview of the Factory System

- Historical Context of the Factory: From Home to Factory

- Key Innovations that Shaped the Factory System

- The Impact of the Factory System on Workers' Lives

- Urbanization and the Rise of Trade Unions

- Advancements in the 20th Century: Management Science and Assembly Lines

- The Role of Automation and Globalization in Modern Factories

- Fascinating Facts about Factories Throughout History

- Conclusion: The Evolution and Future of Factory Systems

Overview of the Factory System

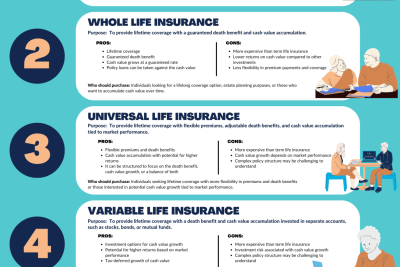

The factory system, at its core, represents a method of production that consolidates resources, labor, and capital to maximize efficiency and output. It is characterized by the concentration of work in a designated building where machinery is used to produce goods. This system arose during the Industrial Revolution in the late 18th and early 19th centuries, marking a significant departure from the previously dominant home-based or artisanal forms of production. The large-scale one factory model allowed for specialization of labor, leading workers to perform specific tasks rather than handling the entire production process.

Central to the success of the factory system were key innovations in technology and organization. The shift from manual labor to mechanized processes dramatically increased the volume of goods produced, which in turn fostered economic growth and the expansion of markets. However, this unprecedented increase in production created complexities in workforce management and resource allocation that would shape the future trajectory of industrial labor.

Historical Context of the Factory: From Home to Factory

Before the factory system was established, the production of goods primarily occurred in households or small workshops. Artisans and craftspeople crafted items by hand, governing their own work hours, conditions, and production rates. Within this domestic system, skilled workers maintained a close connection with their craft, allowing for creativity and personalization. However, as demand for goods grew, particularly during the late 18th century, this model proved insufficient to meet the burgeoning needs of an expanding market.

The transition to a factory-centric approach began with the advent of new technologies, such as the spinning jenny and the power loom, which enabled quicker processing of raw materials. The first one factory model emerged as entrepreneurs sought to streamline production methods and capitalize on the efficiency that mechanization offered. Workers were drawn from rural areas to urban factories, seeking employment opportunities and better wages, leading to a mass migration that forever altered demographic patterns.

Key Innovations that Shaped the Factory System

The Industrial Revolution was defined by a series of technological advancements that transformed the manufacturing landscape. One of the key innovations was the introduction of steam power, which allowed factories to operate machinery at unprecedented speeds and scales. This not only increased productivity but also reduced the reliance on water sources for power, enabling factories to be established in urban settings far from rivers.

Additionally, the concept of interchangeable parts revolutionized manufacturing. Pioneered by innovators like Eli Whitney, this practice allowed for the mass production of goods with standardized components. As a result, repairs became easier, costs decreased, and a range of products could be manufactured more quickly within a single one factory setup.

The Impact of the Factory System on Workers' Lives

The rise of the factory system had profound implications for workers. While it created new job opportunities and the potential for higher wages, it also subjected workers to challenging conditions. Laborers faced long hours, often working over twelve hours a day, six days a week in poorly ventilated and unsafe environments. The industrial setting diminished the sense of craftsmanship, reducing workers to mere cogs in a larger machine.

This exploitation eventually led to widespread discontent among workers, providing fertile ground for the growth of the labor movement. The stark conditions and low wages motivated laborers to organize, leading to the establishment of trade unions in the late 19th century. These unions aimed to advocate for workers' rights, seeking better wages and conditions, which signified the beginning of a broader struggle for labor rights that continues today.

Urbanization and the Rise of Trade Unions

The emergence of factories played a crucial role in driving urbanization. As production shifted to urban settings, people flocked to cities in search of jobs, resulting in rapid population growth in many areas. This urbanization brought about significant social changes as communities adapted to life in densely populated areas. However, it also led to a range of challenges, including poor living conditions, inadequate infrastructure, and increased pressure on public services.

Amidst this backdrop, the rise of trade unions became a vital counterbalance to the power of factory owners. Workers banded together to advocate for their rights and negotiate better conditions. From strikes to collective bargaining, unions played an essential role in shaping labor laws and social reforms aimed at protecting workers. The struggle of these unions was a testament to the resilience of factory workers, marking a pivotal chapter in the history of labor relations.

Advancements in the 20th Century: Management Science and Assembly Lines

The 20th century ushered in significant advancements in the factory system, particularly through the application of management science and the introduction of assembly lines. Pioneered by figures such as Henry Ford, the assembly line revolutionized manufacturing by breaking down the production process into smaller, repetitive tasks. This approach maximized efficiency in production and allowed companies to produce goods on a massive scale at lower costs.

The efficiency brought about by the assembly line exemplified the principles of scientific management, which sought to optimize workflow and improve productivity by analyzing tasks in detail. This innovation further solidified the role of the one factory model in modern economies, creating a new standard in manufacturing processes that remains influential to this day.

The Role of Automation and Globalization in Modern Factories

As the century progressed, the rise of automation and globalization further transformed factory operations. Automation technology, including robotics and artificial intelligence, has streamlined production processes, enhancing efficiency while reducing the need for human intervention in certain tasks. This shift has led to significant changes in the labor market, as traditional factory jobs have diminished, while new roles in tech-driven manufacturing environments have emerged.

Simultaneously, globalization facilitated the outsourcing of production to developing countries, where labor costs were significantly lower. This trend has allowed companies to maintain competitiveness in a global market, but it has also raised ethical and economic debates regarding labor conditions and the impact on economies in more developed regions. The one factory concept has evolved into a network of global operations, making the factory system increasingly intricate and interdependent.

Fascinating Facts about Factories Throughout History

- Did you know that the first mechanized cotton mill was built by Richard Arkwright in 1771? It marked a significant milestone in factory history.

- The term "factory" is derived from the Latin "facere," meaning "to make or do," reflecting the essence of what factories represent.

- During the early 20th century, Ford’s assembly line dramatically reduced the production time of a Model T car from over 12 hours to just over 90 minutes.

- Factory conditions were so grim in the early days of industrialization that it led to the introduction of child labor laws, which aimed to protect vulnerable populations from exploitation.

- Some modern factories employ advanced technologies, such as 3D printing, which allows for custom and flexible manufacturing processes.

Conclusion: The Evolution and Future of Factory Systems

The evolution of the factory system has been a remarkable journey that reflects broader societal changes and technological advancements. From its origins in home-based craftsmanship to the modern one factory model characterized by automation and globalization, the factory system has played a pivotal role in shaping economies and influencing social structures. While challenges remain, such as ensuring fair labor practices and adapting to new technologies, the factory system continues to adapt and evolve.

As we look to the future, the ongoing integration of advanced technologies and shifts in global economic dynamics will undoubtedly continue to redefine what factories look like and how they operate. Understanding the history and impact of the factory system is crucial as we navigate these changes, ensuring that the lessons learned are applied towards creating a more equitable and sustainable manufacturing environment.

Did you find this article helpful? One Factory: Overview, History, and Fascinating Facts See more here General.

Leave a Reply

Related posts