How can I successfully manage stocktaking and inventory

Managing stocktaking and inventory is a critical aspect of any successful business. It not only helps in maintaining the availability of products but also affects the overall financial health of an organization. In today’s competitive market, effective inventory management can set a business apart, ensuring that they can meet customer demand without excess stock that ties up valuable resources. Understanding the process of stocktaking and how to implement it successfully can lead to significant improvements in operational efficiency.

The purpose of this article is to delve into the fundamentals of stocktaking and provide a comprehensive guide for businesses looking to enhance their inventory management practices. We will cover essential principles, methods, and the latest technologies available for businesses aiming to achieve accuracy in their stock levels. From understanding what stocktaking entails to implementing advanced inventory management systems, this article serves as a roadmap for business owners and managers alike.

- Understanding Stocktaking and Inventory Management

- Importance of Accurate Inventory Management

- Key Principles of Effective Stocktaking

- Choosing the Right Method for Inventory Management

- Implementing Inventory Management Systems

- Best Practices for Conducting Stocktakes

- Dealing with Common Stocktaking Challenges

- Leveraging Technology for Improved Accuracy

- Analyzing Inventory Data for Better Decision Making

- Conclusion: Enhancing Inventory Management Success

Understanding Stocktaking and Inventory Management

Before we can effectively manage stocktaking, it is essential to understand what it encompasses. Stocktaking refers to the process of counting and verifying the items in your inventory. This process can be a physical audit, where actual counts are taken, or it can involve examining inventory records to ensure they match the physical stock. The key goal is to ensure that there is a consistency between what is reported and what is physically available.

Definition of Inventory Management

Inventory management is the systematic approach to sourcing, storing, and selling inventory—both raw materials and finished goods. It involves tracking inventory levels, orders, sales, and deliveries. Effective inventory management helps businesses to minimize costs and optimize the availability of products, making it vital for operational success.

Importance of Accurate Inventory Management

Accurate inventory management is crucial for several reasons. First and foremost, it ensures that businesses do not overstock or understock their products. Overstocking can lead to increased holding costs, while understocking may result in missed sales opportunities and diminished customer satisfaction. Therefore, implementing accurate stocktaking practices can significantly impact the bottom line.

Customer Satisfaction

Maintaining adequate stock levels is essential for fulfilling customer orders promptly. When customers find that a product is out of stock, their satisfaction diminishes, and it can lead to lost sales. Businesses that practice regular stocktaking are better equipped to keep track of inventory levels, ensuring that they can meet customer demands without delay.

Key Principles of Effective Stocktaking

To successfully conduct stocktaking, businesses should adhere to certain principles. Some of the key principles include:

- Regular intervals: Conduct stocktaking consistently, whether weekly, monthly, or quarterly, to stay updated on inventory levels.

- Accurate records: Maintain clear and accurate records of all stock movements to facilitate easier stocktaking.

- Employee training: Ensure that staff involved in stocktaking are well-trained and understand the importance of the task.

Choosing the Right Method for Inventory Management

The method of stocktaking chosen by a business can vary based on its size, type of inventory, and operational needs. Here are some common methods:

Perpetual Inventory System

This method continuously tracks inventory levels in real-time. Each time a sale is made or a receipt is processed, the inventory count updates automatically. This is an effective way to maintain accurate stock levels.

Periodic Inventory System

With this method, a business counts inventory at specific intervals, often quarterly or annually. This method is simpler but can lead to discrepancies between counts.

Implementing Inventory Management Systems

Modern businesses often integrate inventory management systems to streamline their stocktaking processes. These systems can automate many aspects of inventory management, reducing human error and providing real-time data. When selecting an inventory management system, businesses should consider:

- Scalability: Choose a system that can grow with your business.

- Ease of Use: Ensure that the system is user-friendly for all relevant employees.

- Integration: Look for systems that can easily integrate with existing software, such as accounting and sales platforms.

Best Practices for Conducting Stocktakes

When it comes to executing effective stocktakes, businesses should follow these best practices:

- Plan and Prepare: Ensure thorough planning before performing a stocktake. Schedule it during a slow period to minimize disruptions.

- Count Methodically: Use a systematic approach when counting, often from a designated starting point and moving through the stock logically.

- Double-Check Counts: Have another employee recheck counts to ensure accuracy.

Dealing with Common Stocktaking Challenges

While stocktaking is essential, it is not without its challenges. Common challenges include:

Discrepancies in Inventory Counts

Discrepancies can arise from theft, misplacement, or clerical errors. Regular stocktaking can help to catch and address these issues promptly.

Time Constraints

Conducting stocktaking can be time-consuming but planning and utilizing technology can streamline the process and reduce time spent.

Leveraging Technology for Improved Accuracy

The role of technology in inventory management cannot be overstated. Advanced tools such as barcode scanners, RFID tags, and inventory management software can significantly enhance the accuracy of stocktaking. By automating the data collection process, businesses can minimize the risk of human error while ensuring real-time tracking of inventory levels.

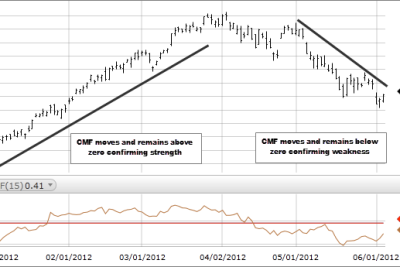

Analyzing Inventory Data for Better Decision Making

Once stocktaking is completed, the next step is to analyze the data collected. Businesses should use this data to identify trends, forecast future inventory needs, and make informed purchasing decisions. This analysis not only enhances operational efficiency but also contributes to strategic planning, ensuring that businesses are poised for growth.

Conclusion: Enhancing Inventory Management Success

In conclusion, successfully managing stocktaking and inventory requires careful planning, effective methodologies, and the right tools. By understanding the importance of accurate inventory management, adhering to best practices, leveraging technology, and analyzing data, businesses can enhance their stocktaking success dramatically. Continuous improvement in these areas not only increases operational efficiency but also contributes to greater customer satisfaction and overall business profitability.

Did you find this article helpful? How can I successfully manage stocktaking and inventory See more here Education.

Leave a Reply

Related posts