Styrene-Butadiene Rubber (SBR): Properties and Applications

Styrene-butadiene rubber (SBR) is an essential synthetic elastomer that has revolutionized various industries due to its remarkable properties. SBR is primarily composed of two key monomers: approximately 75% butadiene and 25% styrene. Its unique chemical composition allows it to serve as a durable and abrasion-resistant alternative to traditional natural rubber. The widespread use of SBR in products such as automobile and truck tires showcases its vital role in enhancing performance and longevity in applications where flexibility and durability are crucial.

The synthesis and evolution of styrene butadiene rubber find their roots in the early 20th century, driven by the need for reliable rubber materials during times of global conflict. Today, the production of SBR aligns with industry standards and safety protocols, affirming its importance in the rubber sector. As we delve deeper into the history, chemical structure, properties, and diverse applications of SBR, it becomes evident that this synthetic rubber is more than just a replacement for natural rubber; it is an indispensable material that supports innovation across multiple fields.

- History of Styrene-Butadiene Rubber (SBR)

- Chemical Composition and Structure

- Production Process of SBR

- Properties of Styrene-Butadiene Rubber

- Advantages of SBR

- Limitations of SBR

- Applications of SBR in Various Industries

- SBR in Automobile and Truck Tires

- Other Uses of SBR

- Future Trends in SBR Development

- Conclusion

History of Styrene-Butadiene Rubber (SBR)

The journey of styrene-butadiene rubber began in the late 1920s in Germany, where chemists first synthesized it as a response to the growing demand for synthetic alternatives to natural rubber. The initial development was aimed at addressing shortages caused by geopolitical tensions and trade restrictions. With the onset of World War II, the need for robust, reliable materials surged, prompting American chemists to further refine and enhance the properties of SBR.

By the end of the 1940s, SBR production methods had improved significantly, leading to commercial viability and widespread adoption. This synthetic rubber quickly gained popularity, accounting for roughly half of the total global rubber production in subsequent decades. The advancements made during wartime not only established SBR as a key material but also opened doors to various applications beyond just tires, influencing industries ranging from adhesives to coatings.

Chemical Composition and Structure

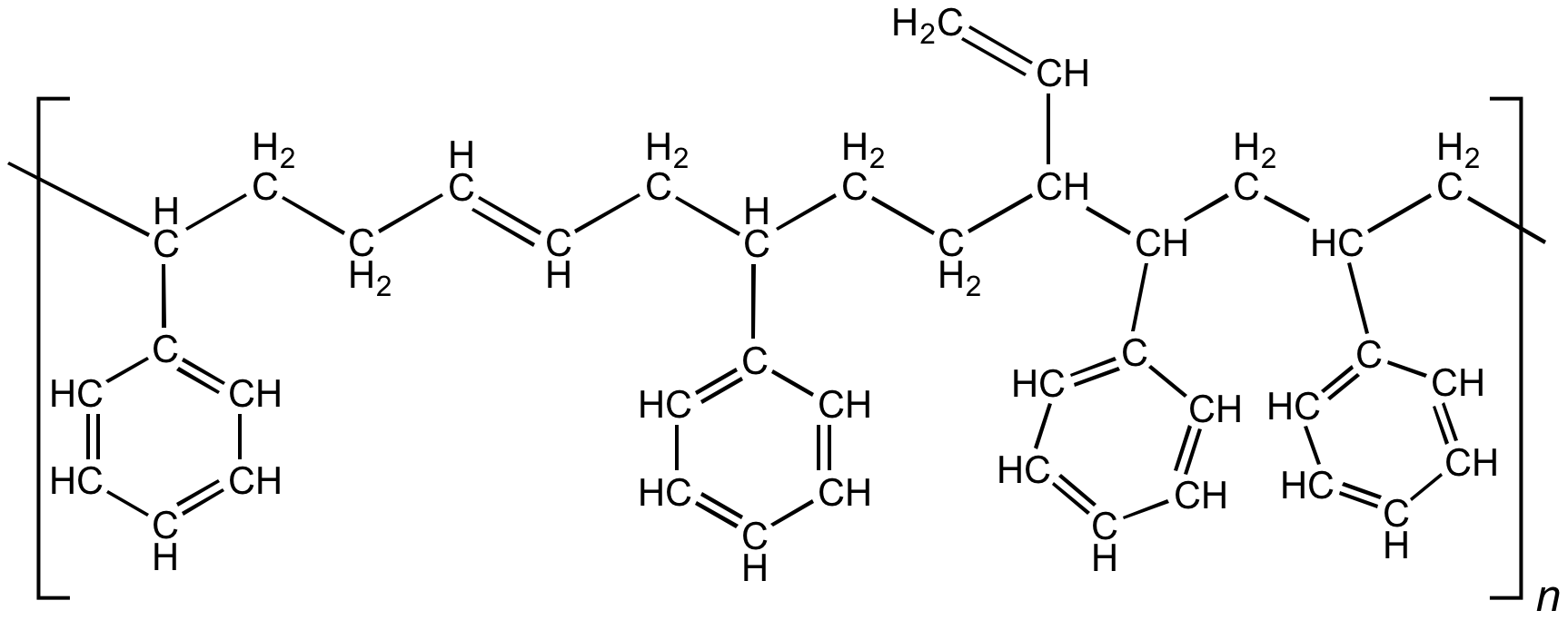

The chemical composition of SBR consists mainly of two monomers: butadiene and styrene. Butadiene, a diene, provides the rubber with elasticity and resilience, while styrene enhances its hardness and abrasion resistance. The typical composition ratio of approximately 75:25 results in a copolymer with a unique set of properties that make SBR suitable for diverse applications.

Structurally, SBR consists of long chains of polymerized monomers, where the arrangement and sequence of butadiene and styrene determine its final properties. The polymer chains exhibit random copolymer characteristics, contributing to the material's overall performance. SBR can exist in two primary forms: emulsion-styrene butadiene rubber (ESBR) and solution-styrene butadiene rubber (SSBR), both of which are produced through different polymerization processes, allowing manufacturers to tailor the properties of SBR for specific applications.

Production Process of SBR

The production of styrene-butadiene rubber involves a complex process of emulsion polymerization, utilizing free-radical initiators to initiate the reaction. This method allows for a high degree of control over the molecular weight and structure of the resultant polymer. Typically, for SBR production, the following steps are involved:

- Preparation of Monomers: Both butadiene and styrene are purified to remove any impurities that could affect the polymerization reaction.

- Emulsion Formation: The monomers are mixed with water, surfactants, and initiators to create a stable emulsion.

- Polymerization: The emulsion is heated in a controlled environment, allowing the monomers to polymerize and form long chains.

- Stripping and Coagulation: The polymer is separated from the water and unreacted monomers through a process of coagulation.

- Drying and Compounding: The raw polymer is dried, then compounded with fillers, additives, and accelerators to enhance its properties before shaping it into desired forms.

This intricate production process enables manufacturers to create SBR with tailored properties and performance characteristics suited to specific applications, ensuring its continued prevalence in the rubber industry.

Properties of Styrene-Butadiene Rubber

Styrene-butadiene rubber (SBR) showcases a range of properties that make it highly desirable for various applications. Among its notable attributes are:

- Durability: SBR exhibits excellent abrasion resistance, making it ideal for heavy-duty applications such as tires and flooring.

- Mechanical Strength: While SBR lacks the inherent strength of natural rubber, its properties can be significantly improved through the addition of reinforcing fillers.

- Weather Resistance: SBR has decent resistance to weathering and ozone, extending the life of products exposed to outdoor conditions.

- Flexibility: The elastic nature of SBR retains its form under stress, allowing for effective use in seals, gaskets, and various molded applications.

Overall, the combination of these properties positions SBR as a critical material in many sectors, where performance and longevity are necessary.

Advantages of SBR

The use of styrene-butadiene rubber comes with a plethora of advantages that contribute to its widespread adoption. Some key benefits include:

- Cost-Effectiveness: Compared to natural rubber, SBR is often more cost-effective to produce, making it a preferred choice for manufacturers.

- Customization: The properties of SBR can be modified through compounding, resulting in tailored formulations for specific applications.

- Availability: As a synthetic rubber, SBR is readily available and not subject to the supply constraints that affect natural rubber.

These advantages underscore the significance of SBR in maintaining competitive production in numerous industries.

Limitations of SBR

Despite its numerous advantages, styrene-butadiene rubber (SBR) has some limitations that must be considered. Notably:

- Low Strength without Fillers: The unfilled form of SBR lacks the tensile strength and durability required for many high-performance applications.

- Poor Resilience: While it possesses excellent elasticity, SBR exhibits lower rebound resilience compared to some other synthetic or natural elastomers.

- Poor Adhesion: SBR can struggle with tackiness, making it less effective in certain adhesive applications unless specially formulated.

Understanding these limitations is crucial for industries that rely on SBR, allowing for strategic decisions regarding its use and formulation.

Applications of SBR in Various Industries

Styrene-butadiene rubber (SBR) is utilized in a diverse array of industries, owing to its versatile properties. These applications span multiple fields, including:

- Automobile Industry: Used predominantly in tires, SBR provides the necessary durability and wear resistance required for vehicles.

- Construction: SBR is often found in flooring materials, coatings, and adhesives for construction projects, where its durability is critical.

- Consumer Goods: From footwear to rubber bands, SBR is integral in the production of many everyday items.

This breadth of applications highlights the impact of SBR on both common products and specialized industries alike.

SBR in Automobile and Truck Tires

The most significant and well-known application of styrene-butadiene rubber (SBR) is in the manufacturing of automobile and truck tires. The formulation of SBR specifically for tires often includes a blend with natural rubber to achieve the desired balance of performance characteristics. Benefits specific to this application include:

- Enhanced Wear Resistance: The durable nature of SBR helps to prolong tire life, allowing vehicles to travel further before replacements are needed.

- Temperature Tolerance: SBR can maintain excellent performance across a wide range of temperatures, which is crucial for tire safety and longevity.

- Resistance to Aging: Tires made with SBR are less affected by ozone and ultraviolet degradation, ensuring they remain effective over time.

These advantages contribute to the safety and reliability of vehicles, which is paramount in the automotive sector.

Other Uses of SBR

Outside of the tire industry, styrene-butadiene rubber (SBR) is utilized in several other applications, reflecting its versatility. Some noteworthy uses include:

- Footwear Manufacturing: SBR is often used in sole production, providing comfort and durability in everyday footwear.

- Adhesives and Sealants: Formulated SBR can improve adhesion properties, making it suitable for a variety of adhesive solutions.

- Flooring Materials: Resilient flooring systems capitalize on the toughness and flexibility of SBR for enhanced longevity.

Each of these uses leverages the unique benefits of SBR, making it integral in enhancing product performance across multiple sectors.

Future Trends in SBR Development

The future of styrene-butadiene rubber (SBR) development is poised for significant advancements, driven by industry demands for enhanced performance and sustainability. Key trends include:

- Improved Polymerization Techniques: Ongoing research into polymerization methods aims to enhance the efficiency and environmental footprint of SBR production.

- Bio-based Materials: Innovations in sustainable materials may lead to the integration of bio-based feedstocks into the SBR production process, reducing reliance on petroleum sources.

- Smart Rubber Technologies: The development of responsive materials equipped with sensors and other technologies could revolutionize the applications of SBR in smart products.

These trends highlight the commitment of the industry to evolve and adapt to ever-changing market conditions and consumer expectations.

Conclusion

In conclusion, styrene-butadiene rubber (SBR) has secured its position as a cornerstone of the synthetic rubber industry due to its unique properties and versatility. With applications spanning from automobile tires to flooring and adhesives, SBR continues to prove its worth. Despite its limitations, ongoing innovations and research promise to enhance the quality and sustainability of SBR, paving the way for exciting developments in the future. As industries evolve and environmental considerations grow more significant, SBR is poised to adapt, ensuring it remains indispensable in modern manufacturing and product development.

Did you find this article helpful? Styrene-Butadiene Rubber (SBR): Properties and Applications See more here Education.

Leave a Reply

Related posts